Robotiikka Akatemia hakee uusia opiskelijoita

Haluatko opiskella hieman eri tavalla?

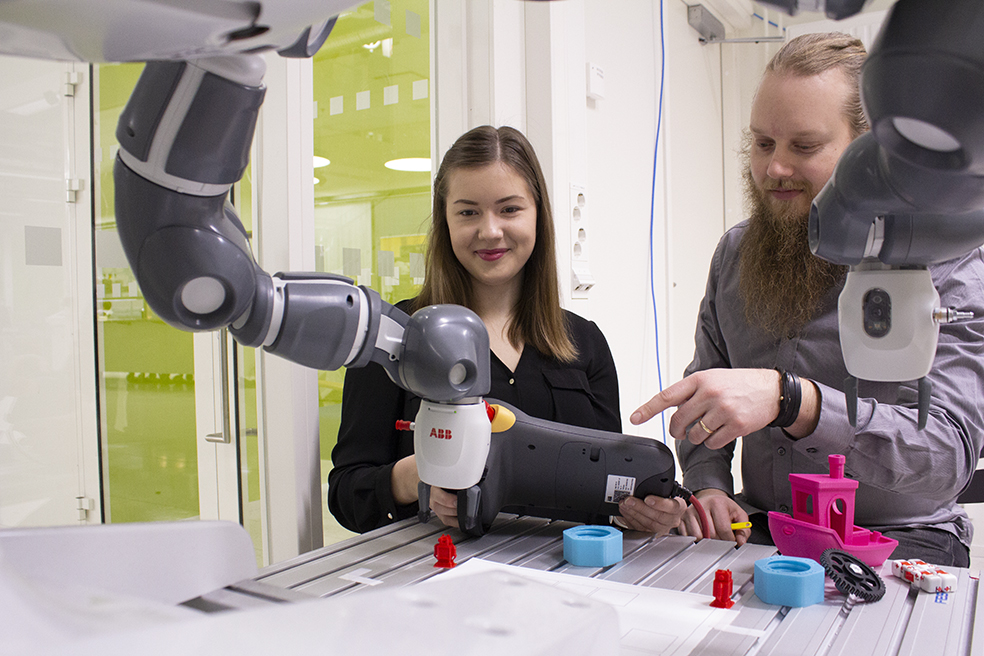

Opiskelu Robotiikka Akatemiassa on erittäin käytännönläheistä. Akatemiassa opiskelevat suorittavat opintonsa työskentelemällä erilaisissa teknologiaprojekteissa. Projektien aiheet tulevat yrityksiltä ja niillä on aina joku konkreettinen tarve eli projektien päätteeksi tarkoitus on aina saada aikaiseksi joku toimiva, asiakkaan tarpeisiin vastaava lopputulos. Se voi olla esim. robottisovellus, tuotannon simulaatio, tuotantosolun muokkaus tai uuden teknologian käyttöönotto. Projektin eri vaiheiden aikana syntyvä osaaminen kirjataan opintopisteiksi, mikäli ohjelmoi projektissa yhteistyörobotin toimimaan osana tuotantolinjaa, kertyy opintopisteitä mm. robotiikasta.

Robotiikka Akatemiaan haetaan opiskelijoita, joilla on suurin osa perusopinnoista käytynä sekä mielellään jo perusteet automaatiosta. Kerrallaan Akatemiassa opiskelee 20-30 opiskelijaa, opiskelijoiden ohjaajina toimivat SAMKin asiantuntijat. Tavoitteena on, että opiskelu on hauskaa, mutta samalla tehokasta. Akatemian opiskelijat valitaan haastattelujen perusteella.

Robotiikka Akatemiassa:

- opiskelet tiimissä ja suoritat loput opintosi yhteistyössä yritysten kanssa opettajien ohjaamana

- työskentelet mielenkiintoisissa projekteissa ja valmistut nopeasti

- kasvat automaation, robotiikan ja digitalisaation ammattilaiseksi

- saat varmasti työharjoittelupaikan

Edellytämme:

- hyvää asennetta työntekoon ja pitkäjänteisyyttä

- kiinnostusta johonkin näistä tai kaikkiin: automaatio/robotiikka/ohjelmointi

- ryhmätyötaitoja

- huumorintajua

Jätä hakemuksesi 27.1. mennessä osoitteessa: https://elomake.samk.fi/lomakkeet/10015/lomakkeet.html

Haastattelut pidetään viikolla 6.

Lisätietoja:

tutkimusjohtaja Petteri Pulkkinen, p. 044 710 3296

Lisää aiheesta

Lue myös

Tilaa uutiskirje

Tilaamalla uutiskirjeen saat uutiset ja tapahtumat uunituoreena sähköpostiisi ja pysyt ajantasalla.